DANNER TUBING PROCESS

DHPS® systems for cord-free and temperature homogenous glass

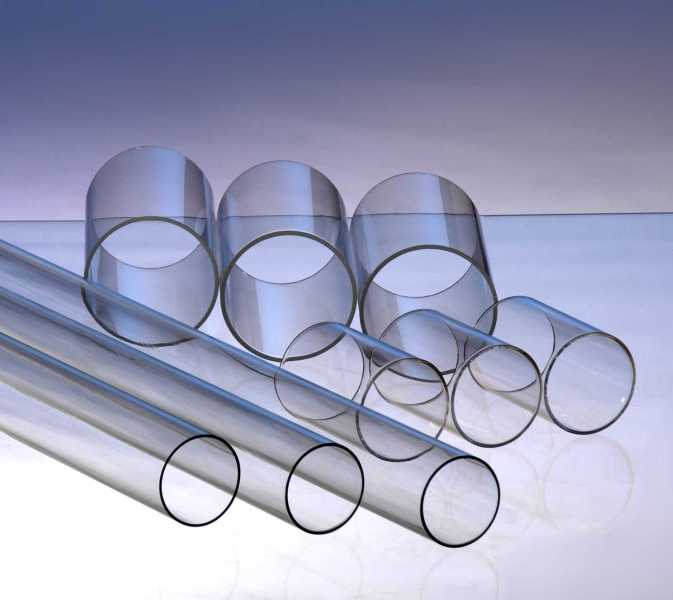

Automated production of glass tubes is primarily carried out by the Danner process. The neutral borosilicate glass is mainly used for the manufacture of ampoules, vials, syringes and pipettes, whilst the neutral amber borosilicate glass is preferred for products which must not absorb any harmful light rays. Amber glass, which is very difficult to produce, is employed for ampoules and small glass tubes.

For the high speed processing machines of the pharmaceutical tubes, it is essential that the manufacturing tolerances of the tubes are extremely tight. To improve the quality of the tube, the use of a platinum feeder based on the DHPS® heating concept instead of a conventional ceramic feeder channel, spout or bowl is shown.

For the high speed processing machines of the pharmaceutical tubes, it is essential that the manufacturing tolerances of the tubes are extremely tight. To improve the quality of the tube, the use of a platinum feeder based on the DHPS® heating concept instead of a conventional ceramic feeder channel, spout or bowl is shown.

DHPS® Platinum Feeder Type 410 for the Danner process is explained in this article. Besides, the DHPS® Platinum Feeder Type 420 is designed for the Vello tubes process.

Using a platinum feeder based on the DHPS® heating concept, the investment retains its values for decades. It does not have to be scrapped after a few years as it is in the case with the refractory material.

By choosing platinum, in addition to increasing the technology standard, a capital investment visible as assets in the company yearly balance is been created.

THE CONVENTIONAL DANNER PROCESS

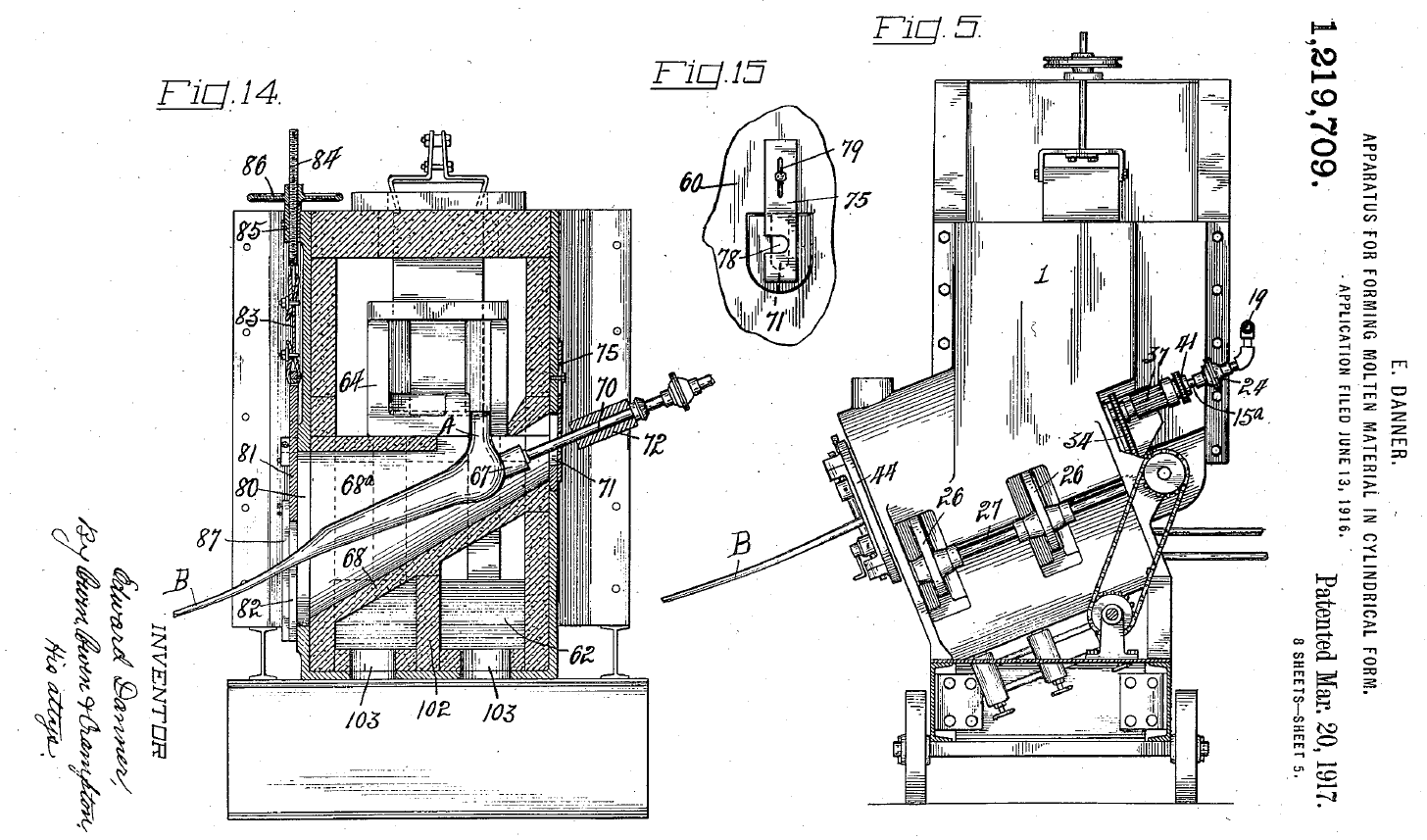

The process of Danner tubing manufacturing has been invented by Edward Danner who was working at Libbey Glass of Toledo/USA. He designed the Danner machine which had mechanized the horizontal method of drawing tubes in 1912. Danner was granted several patents in the year 1917 for the glass making process, which he called: “Apparatus for Forming Molten Material in Cylindrical Form”.

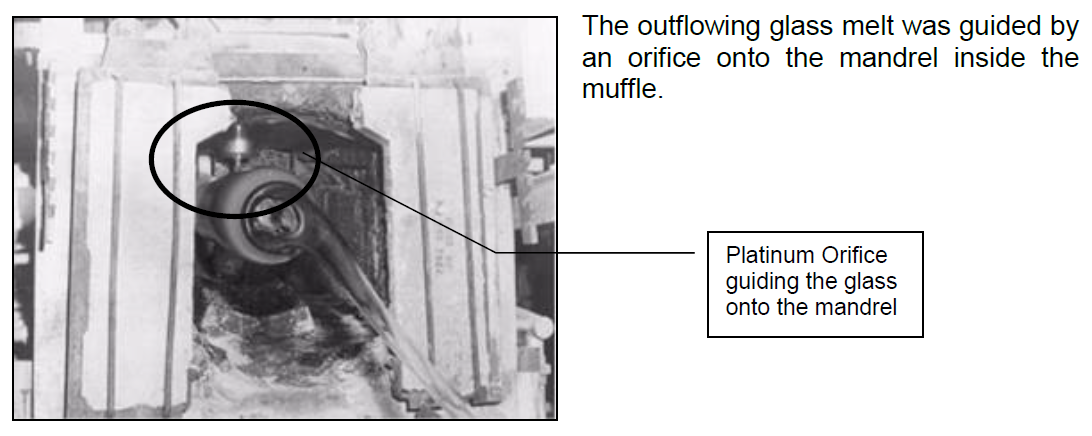

In Danner’s apparatus a supply stream of molten glass flows downwardly onto a continuously rotating downwardly-inclined tapered mandrel and either solid rod or hollow tubing is continuously drawn from the lower or discharge end of the mandrel. The working portion of the mandrel as well as the flowing supply stream and deposited glass surrounding the working portion of the mandrel are all enclosed in a heated chamber or muffle to control glass temperatures to obtain a uniform product.

In Danner’s apparatus a supply stream of molten glass flows downwardly onto a continuously rotating downwardly-inclined tapered mandrel and either solid rod or hollow tubing is continuously drawn from the lower or discharge end of the mandrel. The working portion of the mandrel as well as the flowing supply stream and deposited glass surrounding the working portion of the mandrel are all enclosed in a heated chamber or muffle to control glass temperatures to obtain a uniform product.

Conventionally in the manufacture of glass rod or tubing as practiced by the Danner process, a tubular refractory sleeve is mounted on a metallic blowpipe which serves to permit the molten glass to flow thereon due to the rotation of the mandrel as well as the action of gravity in combination with lengthwise drawing of the material therefrom in a substantially horizontal direction.

In the later times the tube drawing process was improved by redesign the Muffle and the Danner mandrel.

In the later times the tube drawing process was improved by redesign the Muffle and the Danner mandrel.

The Muffle has been connected to the furnace and Danner machine by a refractory channel. In this feeder channel, the glass cools down from the melting temperature to a temperature similar to the temperature of glass flowing onto the Danner mandrel.

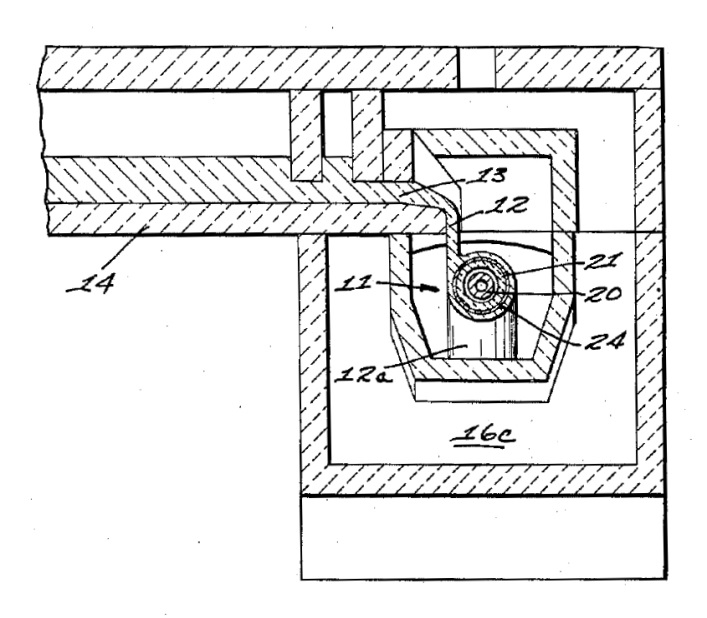

|

|

This generally requires temperature reductions of 100-150°C. The heat transfer of the glass in the feeder channel is passed through the four boundary surfaces in the ceramic feeder channel. The objective is to cool the glass flowing inside the feeder channel, uniformly from all sides. However, there is always a typical temperature gradient in the cross section of the glass bath, characterised by a higher temperature of the glass in the centre and lower temperature on the peripheries.

The temperature differences are stronger if the conditions for the feeder channel are getting more difficult. This is the case, if the output varies due to the produced different tube diameter or if the maximum output has to be set, i.e. large diameter tubes with thick walls are to be drawn.

In many glass plants, special feeder channel designs and heating systems have minimised the temperature variations, but not completely eradicated this problem. The lack of uniformity of temperature of the glass can usually not be compensated in the following refractory feeder head, spout or bowl with the Lip block or unheated orifice.

Other disadvantages are caused by the deterioration of the chemical homogeneity of the glass melt in the ceramic feeder channel. Constituents such as zirconium oxide from the refractory material do not dissolve well and form cords in the tubes.

It is well known that using conventional ceramic feeders will result in a low quality process because of several reasons:

To counteract the non-homogeneous glass surface, NEG of Japan introduced ceramic screw stirrers. The stirrers prevent the cooling surface glass layers - with increasing concentrations of SiO2 - submerging in the parent glass.

The increased local velocity of the glass melt using stirrers will result in an increase of erosion of the refractory material around the stirrers. This solution gave only partial better quality of the produced tubes.

ORIFICES AND THEIR USE

In the last years a combination of the covered feeder channels and platinum cladded orifice rings has been used in the tubing industry.

Temperature differences are originated from feeder channel which will flow into the orifices will result in temperature inhomogeneity shown as cords of the final tube.

So-called needles or stirrers with low or no efficiency for homogenising of the glass melt have been sometimes used as dosing.

So-called needles or stirrers with low or no efficiency for homogenising of the glass melt have been sometimes used as dosing.

The combination of the needle and orifice is a good solution for higher yield ratio of the product. As a form of erosion protection sometimes the parts are coated or cladded with platinum but the main disadvantage remain:

No thorough stirring of the glass melt and therefore no homogeneity of the outflowing glass melt.

For both concepts, with or without needle, the temperature distribution of the Danner Muffle, where the Danner mandrel is installed, cannot compensate the inhomogeneity of the outflowing glass melt. In which ever solution the heating of the Danner Muffle is been realised, either electrically or direct or indirect gas fired, the influence of temperature distribution in the Muffle will influence the outflowing glass viscosity.

For both concepts, with or without needle, the temperature distribution of the Danner Muffle, where the Danner mandrel is installed, cannot compensate the inhomogeneity of the outflowing glass melt. In which ever solution the heating of the Danner Muffle is been realised, either electrically or direct or indirect gas fired, the influence of temperature distribution in the Muffle will influence the outflowing glass viscosity.

In summary, the conventional Danner ceramic feeder leads to chemical and thermal inhomogeneity of the glass melt and therefore to fluctuation of the tube diameter and wall thickness. This means that the tight dimensional tolerances of the glass tubes required by the end-user to reach the famous Schott quality cannot be achieved.

tube diameter and wall thickness. This means that the tight dimensional tolerances of the glass tubes required by the end-user to reach the famous Schott quality cannot be achieved.

THE CONCEPT OF WORKING END

WITH PLATINUM FEEDER

Best solution for the fabrication of Neutral glass tubes with a thermal expansion of alpha 50 has been introduced by Schott of West-Germany under the brand ‘FIOLAX’ already in early 1960ies in the factory at Mitterteich.

The basic concept is to avoid knots and temperature inhomogeneity by using a working end to feed the glass melt to the DHPS® Feeder. This concept has lead Schott to be the No.1 worldwide in quality and quantity of production of glass tubes.

The Working end is receiving the glass melt from the furnace through a throat. The working end is equipped with electrodes to ensure convection of the glass melt in combination with burners situated at suitable positions.

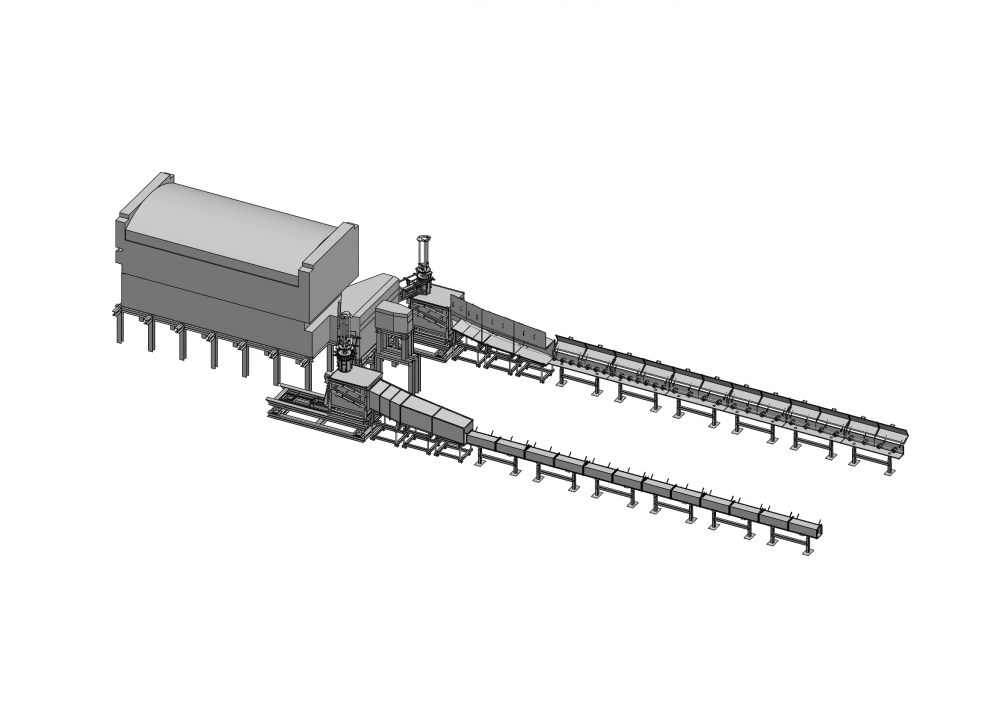

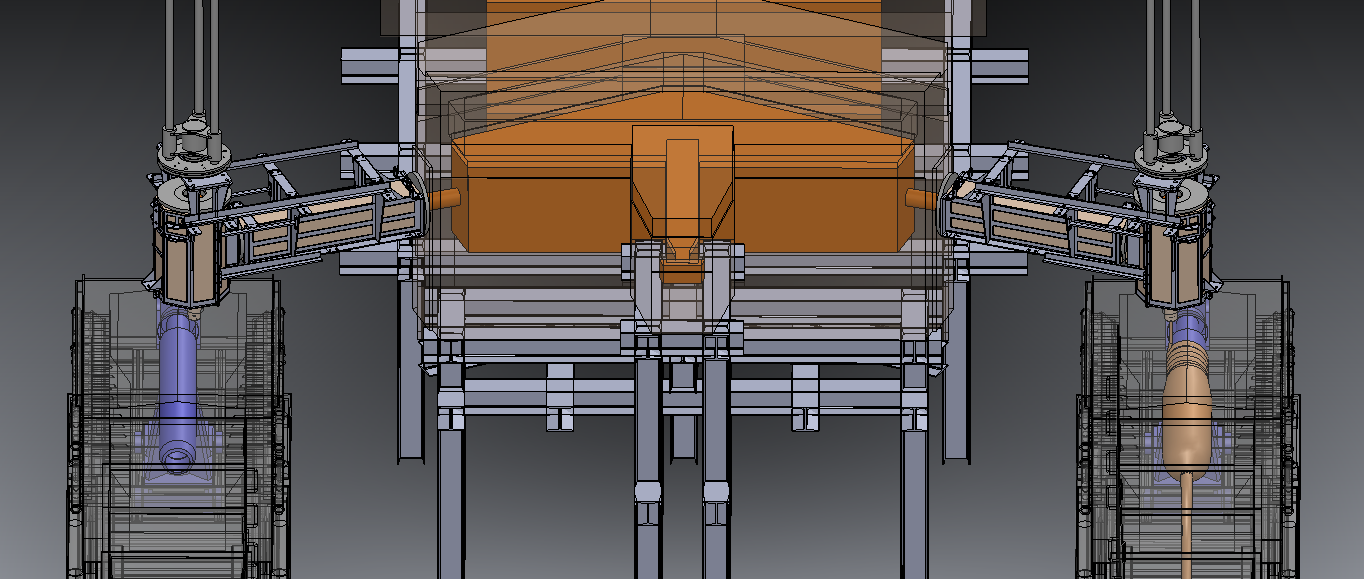

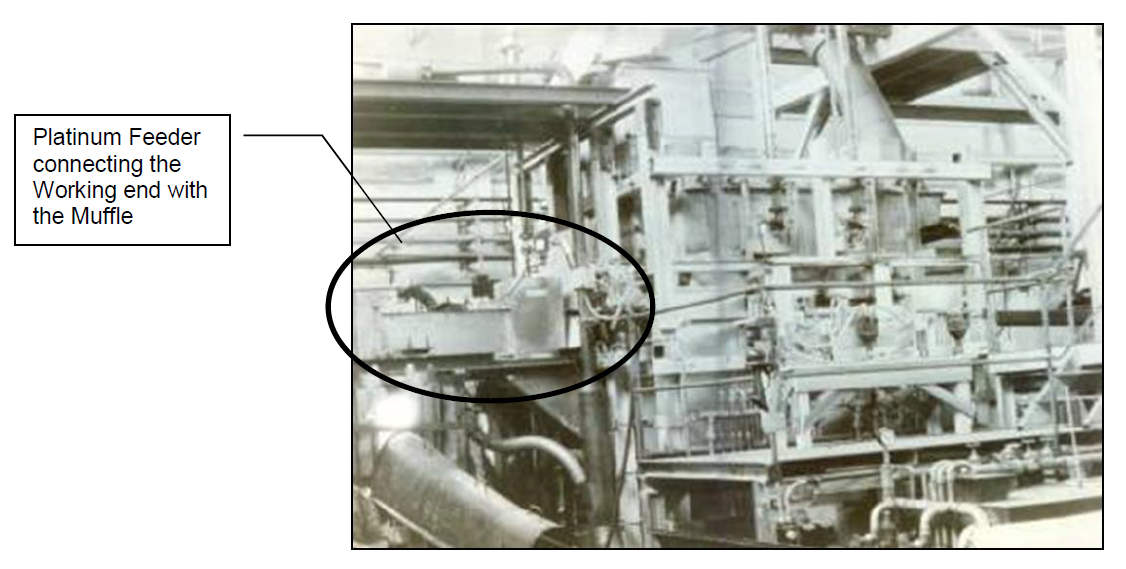

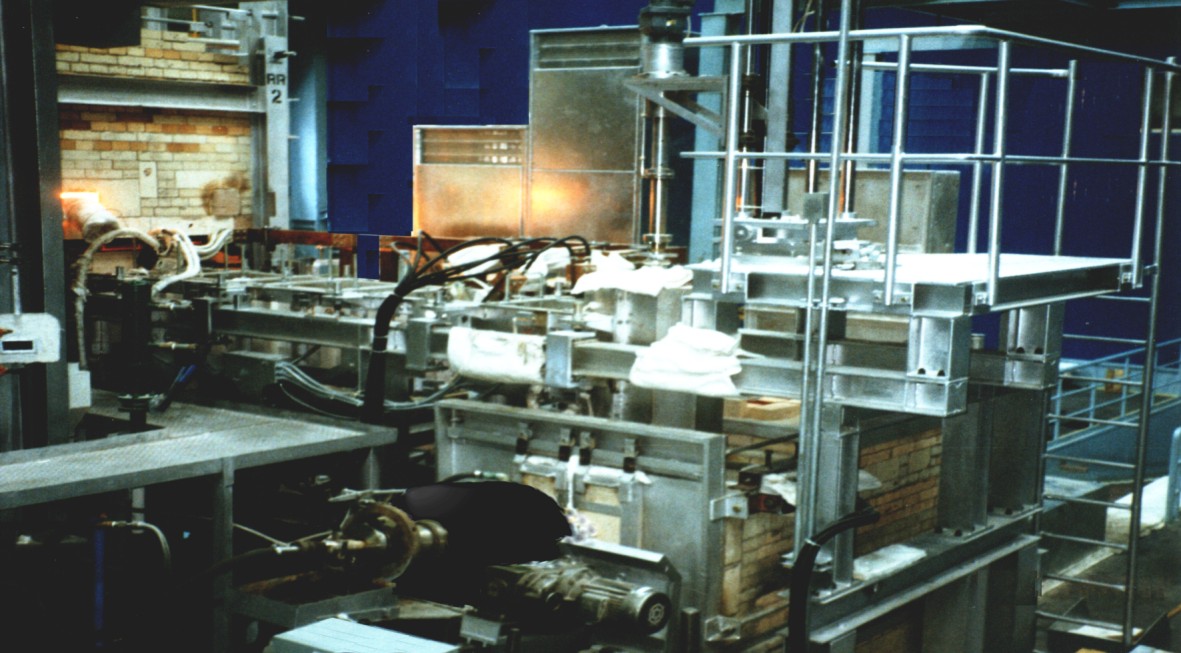

2 sets DHPS® Platinum Feeder connected to the Working end

The use of zirconium material as refractory in the furnace and working end leads to the operation with one or more bottom drains so that zirconium rich bottom glass can be removed from time to time. As a consequence of the reduced velocity in the working end, the glass-zirconium oxide particles will be drawn out of the Bottom drains.

Already 50 years ago Schott of Germany had started to produce tubes with Platinum Feeders, which were connected to a working bay.

Since the use of Oxy-fuel firing, the yield rates in terms of knots have been improved drastically. The specific heat pattern inside the working end makes this solution in combination with DHPS® Feeder a proven unbeatable solution, if high quality of glass tubes with high yield is the target.

DHPS® PLATINUM FEEDER TYPE 410

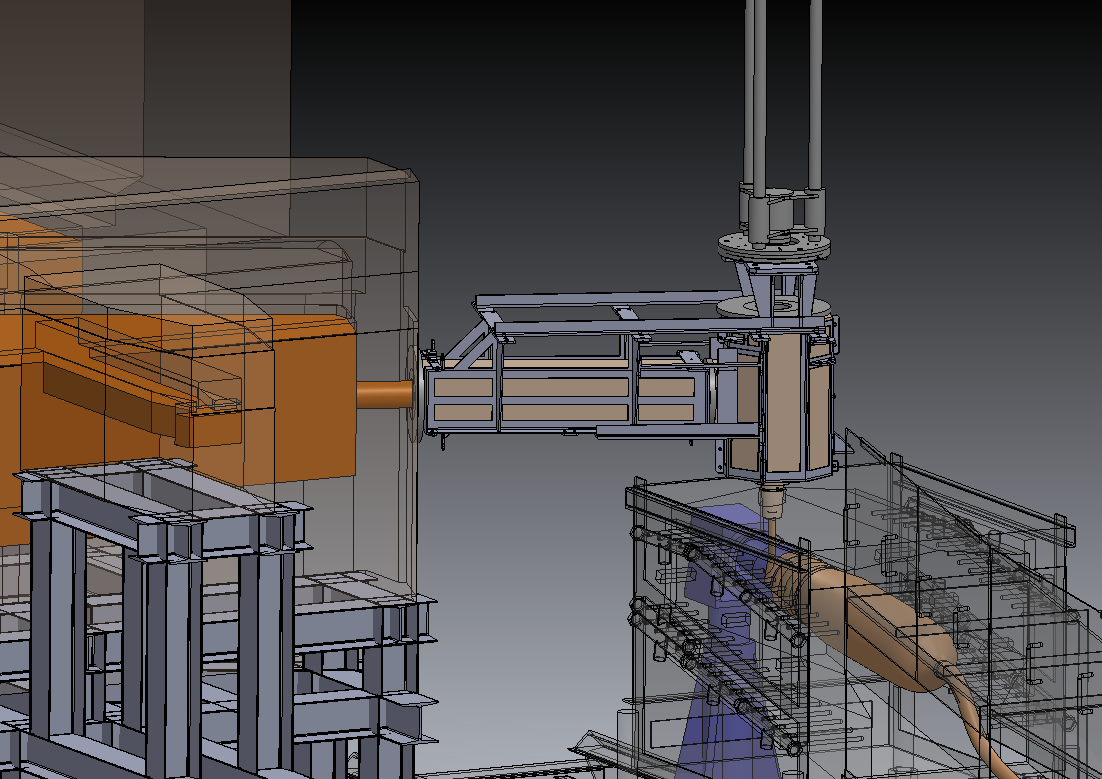

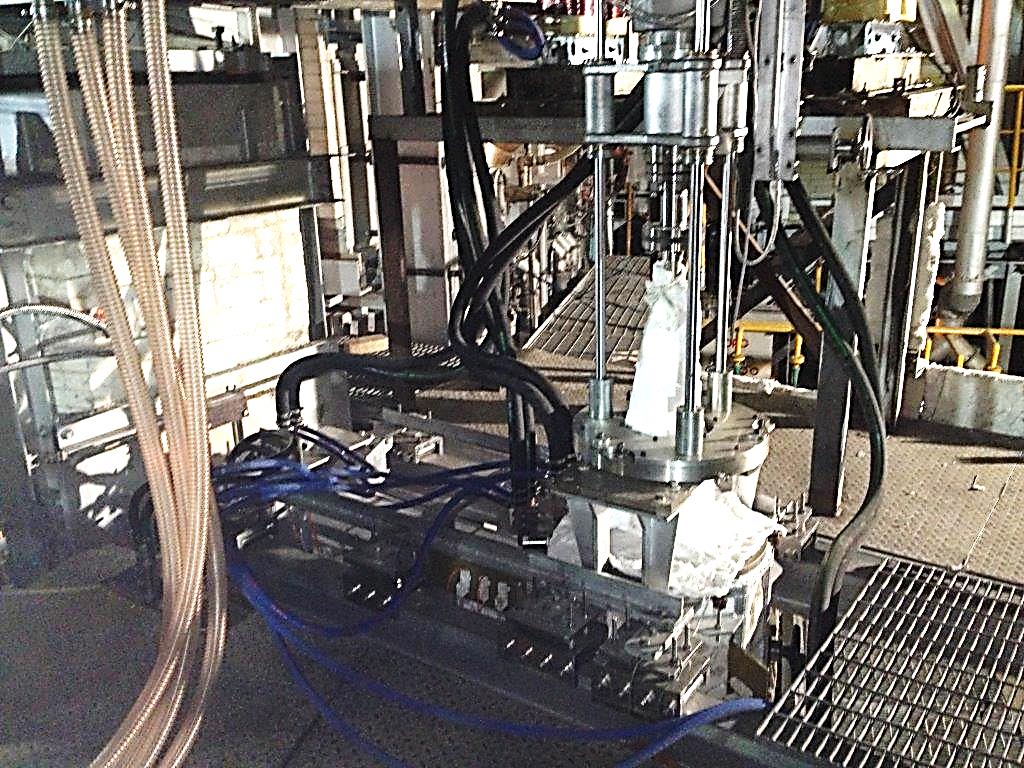

Following the Schott concept of the 1960ies, the tightest tolerance ranges for the production of pharmaceutical tubes can be achieved by connecting the electrically direct heated Platinum Feeder directly to the working-end.

By using this operation concept, the cooling of the glass takes place in the platinum system and the refractory channel with all its limitations can be eliminated. The constant corrosion of the refractories, which is found in the final product, is avoided.

By using this operation concept, the cooling of the glass takes place in the platinum system and the refractory channel with all its limitations can be eliminated. The constant corrosion of the refractories, which is found in the final product, is avoided.

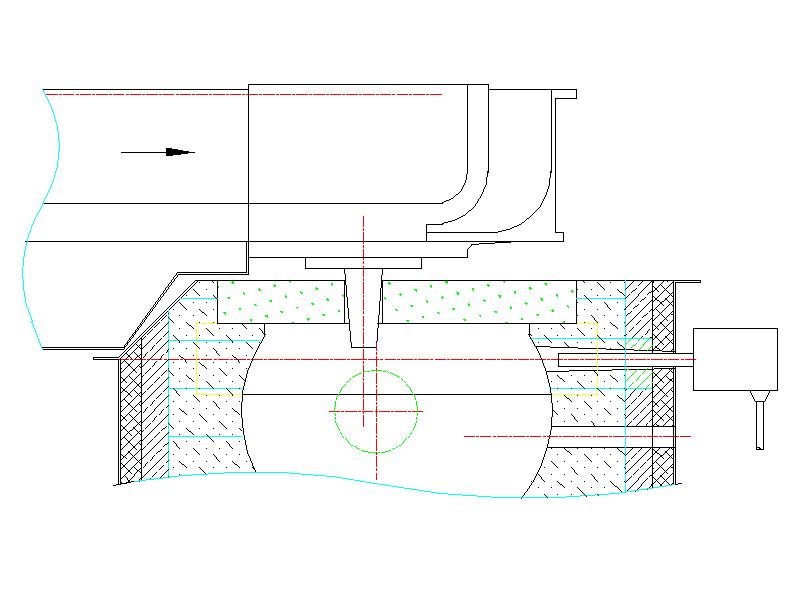

DHPS® Platinum Feeder Type 410

Considering that the platinum feeder is replacing the refractory spout less corrosion products are entering the final product. The DHPS® Feeder ensures is a problem free production during the life period of about 2-3 years.

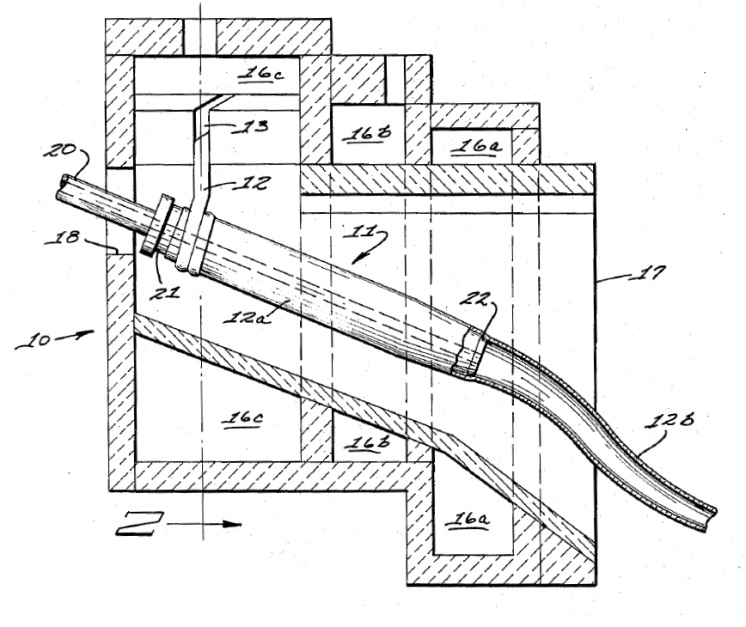

The glassmelt flows from the furnace through a throat into the working end, in which zirconium contenting glass will be drained out. Only ‘virgin glass’ is entering the through a horizontal whole underneath the Glasslevel into the DHPS® Feeder, which is fitted in a steel frame with well calculated surrounding isolation.

The glassmelt enters into a horizontal platinum tube (Entrance tube) and flows into the vertical the Danner or Stirrer cell. The Entrance tube serves as a geometric connecting link between the working end and Stirrer cell and is able to adjust/cool the temperature of the glass melt within a certain temperature range in order to achieve optimum glass viscosity for the outflowing glass stream.

The dosing stirrer is driven by a stirrer mechanism and installed above the Danner cell rotating a special designed dosing Stirrer.

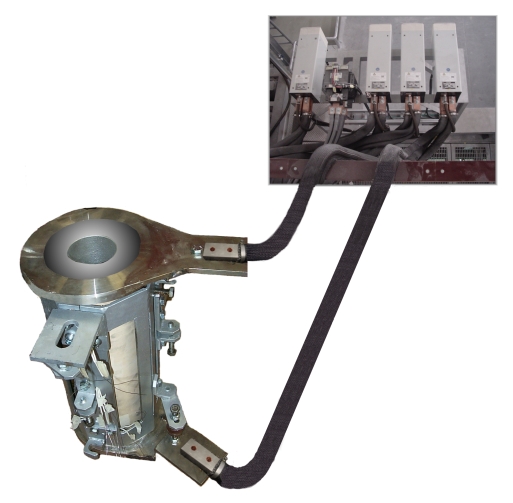

The DHPS® Feeder is electrically direct heated through 2-4 separately adjustable heating zones. Adjustment of the input power enables to influence the temperature of the platinum tubes (and with this also the glass melt) in relation to the heating zones. Thyristors are used as power output stages for the direct electrical heating of the platinum tubes.

The DHPS® Feeder is electrically direct heated through 2-4 separately adjustable heating zones. Adjustment of the input power enables to influence the temperature of the platinum tubes (and with this also the glass melt) in relation to the heating zones. Thyristors are used as power output stages for the direct electrical heating of the platinum tubes.

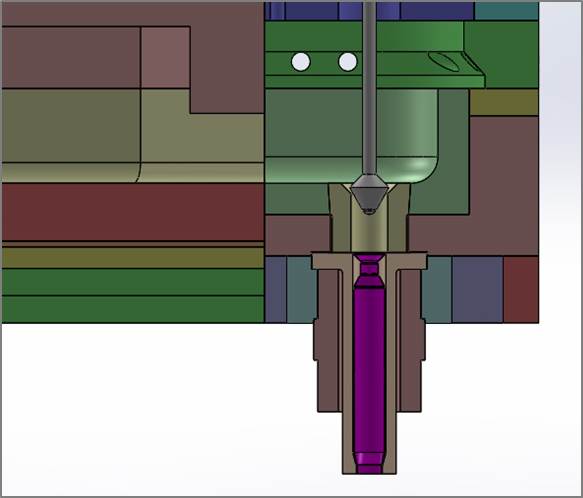

DHPS® Entrance tube and Danner Cell Type 410

Temperature feedback sensing is carried out by thermo-elements installed in geometrically appropriate positions on the platinum tube. Temperature control and temperature changes are ideal, because the reaction caused by readjustment of the set value takes place within few minutes and is shown its result in the changes of the outflowing glassmelt.

The fact that the glassmelt is controlled and balanced through the fast responding heating, excellent weight constancy of the glass stream and with this, an excellent result of the final product in terms of wall thickness and diameter constancy can be reached.

The Dosing Stirrer which is located in the Danner cell fulfils two functions.

Firstly, the glass is re-mixed and thermally homogenised. The glass melt is stirred with maximum shear forces in the Danner cell, which results in a homogeneous temperature and eliminates cords created by thermal or chemical inhomogeneity from the melting process or refractory corrosion (e.g alumina etc.).

It is important that the down flowing glass stream is cut dynamically at every point by the Stirrer. The time span of this intensive stirring should not be too short. The duration of the stirring time depends on the output.

Secondly the glass output is mechanically adjusted on a valve principle in combination with the orifice; it is possible to completely stop and restart the glass output in a very short time. This allows a mandrel change to be made in 2 hours.

At the bottom of the Danner cell a orifice is installed, which can be directly heated or not. The part of the orifice facing the glass melt is covered with platinum material. The direct heating concept is applied to the orifice, which has an elliptical outlet for the glass stream flowing onto the Danner mandrel. The possible separate heating of the orifice achieves a constant glass output independent of the temperature changes in the Danner muffle.

At the bottom of the Danner cell a orifice is installed, which can be directly heated or not. The part of the orifice facing the glass melt is covered with platinum material. The direct heating concept is applied to the orifice, which has an elliptical outlet for the glass stream flowing onto the Danner mandrel. The possible separate heating of the orifice achieves a constant glass output independent of the temperature changes in the Danner muffle.

A constant temperature has been created, if the glass melt is flowing out of the orifice.

The orifice is made changeable for different dimensions of the glass stream. In co-ordination of different orifices, quality tubes conforming to international standards (DIN) in the range of 2,0 - 60,0 mm can be produced.

Danner process with DHPS® Platinum Feeder Type 410

The latest installation in India proves that the DHPS® Platinum Feeder Type 410 is essential to prevent failures and defects made in the manufacture of glass tubes, in particular thermal cords and defects of wall thickness and tube diameter.

By using the DHPS® Feeder for high borosilicate / low alpha like amber glass with alpha 60 or lower and flint glass with alpha 50 at yield ratios constantly above 80% for tight tolerances required by the high speed ampoule machine running nowadays, is the only choice.

DHPS® TECHNOLOGY

The following describes the Direct Heated Platinum System (DHPS® ). In this process, the glass flows through Pt-Rh alloys tubes and therefore no longer makes contact with corrosive refractory materials. The precious metal (PGM) tubes are completely filled with glass so that no surface evaporation can occur.

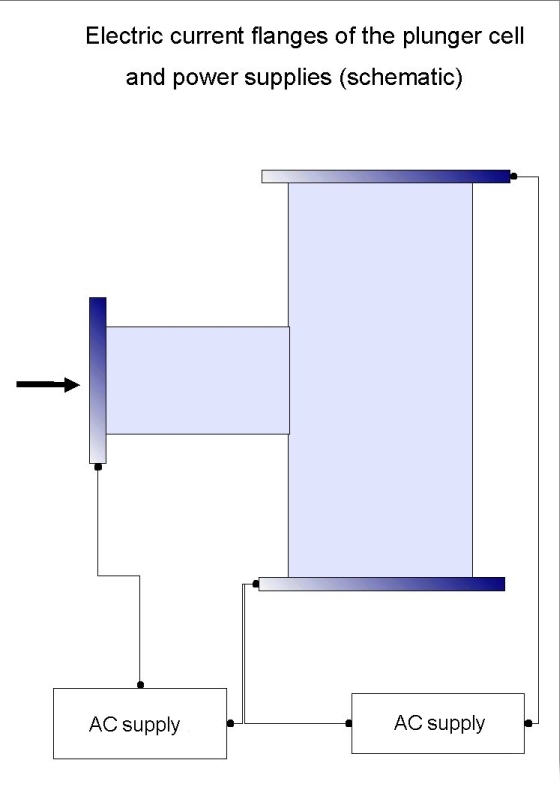

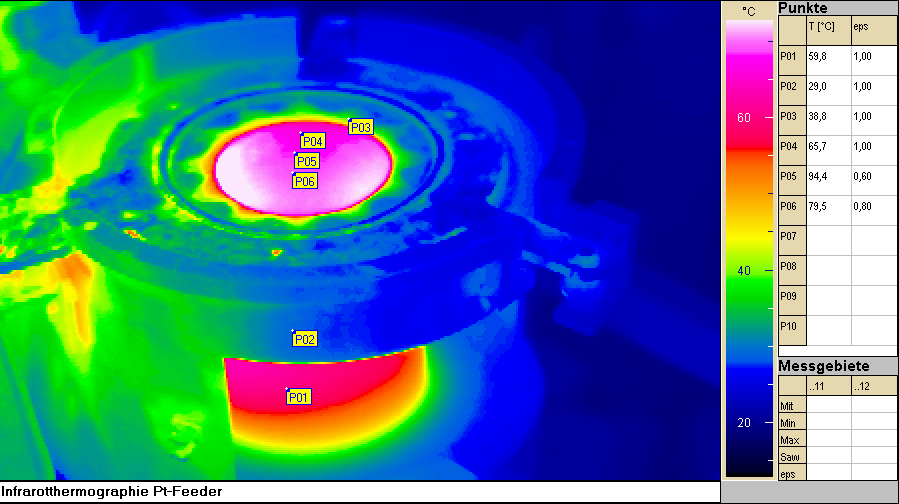

In the DHPS®, an alternating current flows directly through the walls of the Pt-Rh alloys tube system, creating temperature homogeneity around the circumference of the tube which is transmitted to the glass flowing through the tube. The glass has the same thermal conditions all around.

In the DHPS®, an alternating current flows directly through the walls of the Pt-Rh alloys tube system, creating temperature homogeneity around the circumference of the tube which is transmitted to the glass flowing through the tube. The glass has the same thermal conditions all around.

As a result of the low specific resistance of the Pt or Pt/Rh alloy, the heating takes place in the low voltage range - which is a safety benefit. Depending on the application, the voltage requirement is between 2 and 18 V. The type of glass and its application are the factors determining which Pt-Rh alloy is used for DHPS®.

Due to the relatively high temperatures in the DHPS®, the Rhodium content of the Pt-Rh alloy for industrial glass types is between 10% and 30%, whilst a Rh content of 5% is preferred for soda lime and lead glass types. Pure platinum oxide strengthened material is used for optical glass.

Geometric dimensions and the electrical heating circuits are dimensioned according to the glass type and output. This is carried out in conjunction with the engineering and dimensioning of the optimum insulation materials used around the precious metal tubes.

The temperature of the individual heating zones is controlled by thermo-elements, welded directly onto the precious metal tubes at the appropriate control points and linked with temperature controllers using the PID process. Additional thermo-elements show the detailed temperature distribution in the longitudinal feeder axis, and are used to set required temperatures for the heating zones. The short lead times of the control paths allow ideal temperature control for the application.

|

|

Connection of the platinum tube to transformers |

Changes of the required glass temperature are set oscillation-free in only a few minutes. The specified temperatures are kept

Changes of the required glass temperature are set oscillation-free in only a few minutes. The specified temperatures are kept

constant at <0.5K. The direct heating of the platinum feeder in conjunction with the optimum dimensioning and insulation makes it possible to achieve a temperature difference of less than one (1) Kelvin over the tube cross section.

The complete system is monitored and controlled by PLC and can be readily integrated into existing systems.

The design of the external steel frame ensures the thermal expansion of the precious metal assemblies during heating and cooling. This provides a sound footing for a long life of the DHPS®-system.

The modular system allows various functional units of the DHPS®-system to be assembled in sequence to produce the most effective solution to meet customer requirements with minimum use of the precious metals.

SUMMARY

The DHPS® Danner Tubing Process offers several advantages in the manufacture of tubes as there are:

Thermal and chemical homogeneity

• Thermally homogeneous glass is prepared. This provides the basic conditions for drawing tubes with narrow wall thickness tolerances and low external diameter fluctuations.

• Elimination of temperature gradient from the surface of the glass down to the orifice by using DHPS® Platinum Feeder Type 410.

• An automatic adjustment of the temperature with direct heated DHPS®-orifice compensating temperature changes of the Danner Muffle and is guiding the glass at a constant temperature to the Danner mandrel.

• Chemical homogeneity because of no evaporation elements e.g. of boric acid or lead oxide.

Production advantages

• Increase in the effectiveness of the tube drawing, as there is no need to change the spout during the entire life of the feeder. Refractory channels are no longer needed.

• Constancy of the glass output as the orifice is heated directly. Constancy of the cross-sectional area of the glass stream, as orifice is protected by platinum.

• Reduction of exchange time of the Danner mandrel, as the glass output can be stopped and quickly restarted by using the Dosing Stirrer.

• Rapid adjustments of the temperature profile due to the direct heating when changing product diameter or wall thickness.

• Production of quality tubes conforming to international standard (DIN) within a range of 2.0 – 60.0 mm diameter.

• Direct heating of platinum tubes lead to less energy consumption.